-

GuillermoExcellent! Fast delivery! I like to work with you again!

GuillermoExcellent! Fast delivery! I like to work with you again! -

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us.

Perus ColetteIt is my pleasure to do the business with LiFong,they always do the best for us. -

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration.

Robin SeifertI like the products and service provided by LiFong. They really take our interest into consideration. -

SjakThat's true we enjoy doing business with you.

SjakThat's true we enjoy doing business with you. -

Kelly MarshLiFong is one of our desired vendors in China

Kelly MarshLiFong is one of our desired vendors in China -

रायमुंड शेन्कोउत्पाद की गुणवत्ता, प्रतिस्पर्धी मूल्य, हमेशा हमारे प्रमुख आपूर्तिकर्ताओं में से एक

रायमुंड शेन्कोउत्पाद की गुणवत्ता, प्रतिस्पर्धी मूल्य, हमेशा हमारे प्रमुख आपूर्तिकर्ताओं में से एक

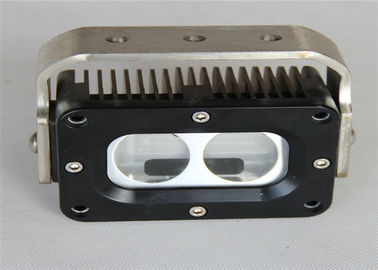

Industrial Mining Lamp Housing Aluminum Heat Sinks Powder Spraying

| Material | Aluminum Alloy | Craft | Die castings,CNC |

|---|---|---|---|

| Aplication | Aluminum Heat Sinks | Surface treatment | Powder Spraying |

| Type | Industrial and Mining Lamp Housing | Size | Customized |

| प्रमुखता देना | aluminum extrusion heat sink,aluminum heat sink extrusions |

||

Industrial and Mining Lamp Housing Aluminum Heat Sinks Die-casting industrial aluminum

Specifications:

1,Main material: Aluminum Alloy

2,Surface treatment: Powder Spraying

3,Demension:L150*W100*H70mm

4,Craft: Die castings,CNC

5,Weight:1374g

Processing technique:

1,Die casting tooling making-prototype/T1-dimension check-sample approval-SOP

2,Die casting-remove water gap-deburring-machining-drilling holes-threading-quality check(dimensions and surface)-electrostatic coating-QC(surface vision checking)-packaging

3,High quality checking outside usage powder coating surface makes very good performance in oxidation resistance and corrosion resistance

Description:

| Product name | Industrial and Mining Lamp Housing |

| Item No. | LF-9280 |

| Material | Die-casting Aluminum ADC12,CNC |

| Surface treatment | Powder Spraying |

| Size | As Customer requirements |

| Packing | As your requirements. |

| Production time | 15-30days,it is up to the order. |

| MOQ | Negotiable |

| payment term | T/T,L/C |

Advantages:

1,Professional research and design team(20person),possess all necessary equipment

2,Strict quality control in each process and finish product quality control

3,Short delivery lead time: 15-30 days

4,Optional for OEM or ODM

5,Comprehensive after-sale service, quick responses for daily communication

![]()